Biogas Production: Turning Food Waste into Renewable Energy

Biogas Production: Turning Food Waste into Renewable Energy

Introduction

Food waste is a global challenge, with an estimated 1.3 billion tons of food lost or wasted annually, contributing to greenhouse gas emissions and resource depletion . However, this organic waste can be transformed into a valuable energy source through anaerobic digestion, a natural process that converts food scraps into biogas—a renewable fuel composed primarily of methane and carbon dioxide . This article explores the process, benefits, challenges, and applications of biogas production from food waste, highlighting its role in creating a circular economy.

The Science of Biogas Production

1. Anaerobic Digestion: Nature’s Recycling Process

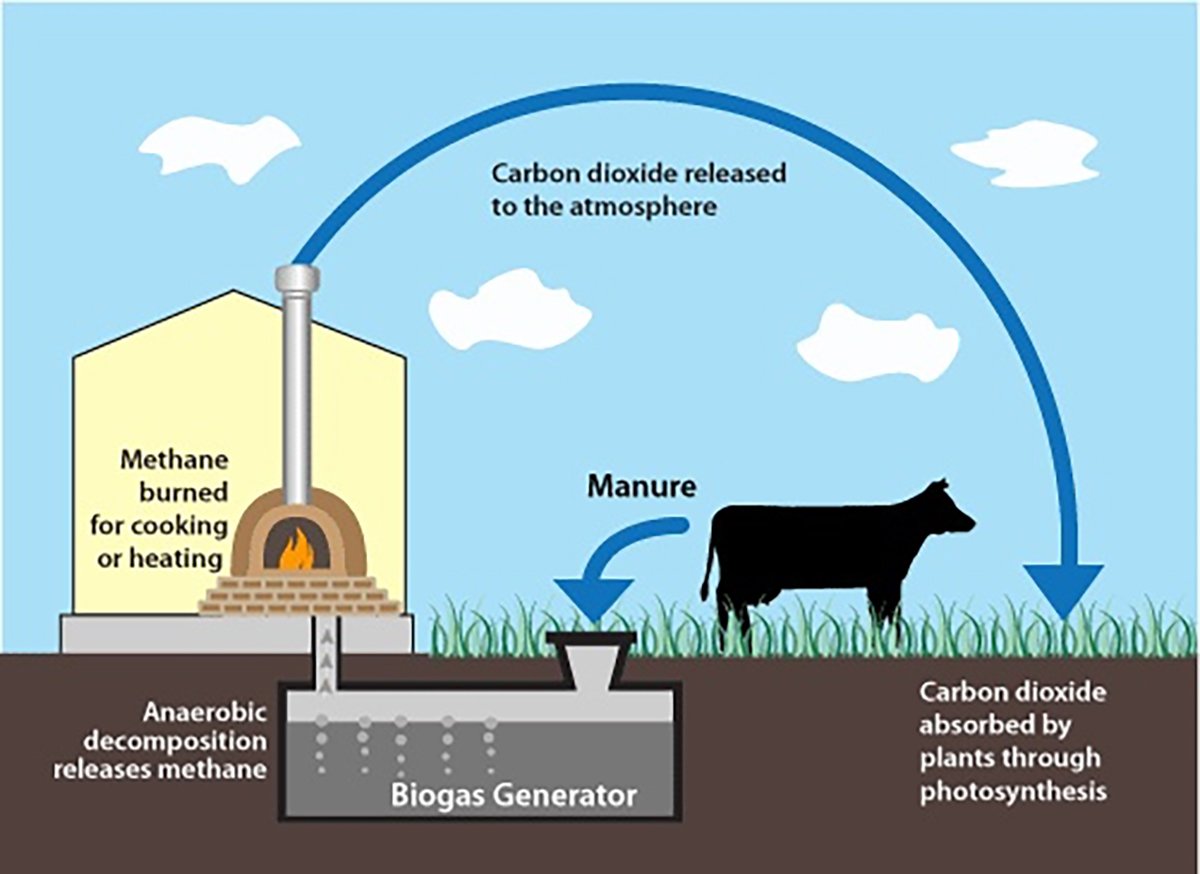

Biogas is produced when microorganisms break down organic matter (e.g., food waste, manure) in the absence of oxygen. This process occurs in four stages:

- 1.Hydrolysis: Complex organic molecules (e.g., carbohydrates, proteins) are broken down into simpler compounds like sugars and amino acids.

- 2.Acidogenesis: Acidogenic bacteria convert these simpler compounds into volatile fatty acids, hydrogen, and carbon dioxide.

- 3.Acetogenesis: Acetogenic bacteria further transform the products into acetic acid, hydrogen, and CO₂.

- 4.Methanogenesis: Methanogenic archaea convert acetic acid and hydrogen into methane (CH₄) and CO₂, the primary components of biogas .

2. Key Feedstocks: From Kitchen Scraps to Farm Waste

- Food Waste: Fruit and vegetable peels, bread, dairy products, and leftover meals are rich in carbohydrates and proteins, making them ideal for biogas production .

- Agricultural Residues: Crop stalks, fruit pulp, and animal manure can be co-digested with food waste to enhance biogas yield .

- Municipal Organic Waste: Sewage sludge and food-processing waste (e.g., brewery grains) are also suitable feedstocks .

3. The Biogas Plant: Step-by-Step Process

- 1.Feedstock Collection and Preprocessing: Food waste is collected from households, restaurants, or farms and transported to the biogas plant. It is then shredded, mixed with water, and sometimes pre-treated (e.g., heating or adding enzymes) to optimize digestion .

- 2.Anaerobic Digester: The preprocessed waste is fed into a sealed digester tank, where anaerobic bacteria break it down over 20–60 days. The tank is maintained at a temperature of 35–40°C (mesophilic conditions) or 50–60°C (thermophilic conditions) for optimal microbial activity .

- 3.Biogas Collection and Upgrading: The produced biogas, which contains 50–70% methane and 30–50% CO₂, is captured and stored. Impurities like hydrogen sulfide are removed through scrubbing to produce biomethane, a high-quality fuel .

- 4.Energy Utilization: The biogas can be used to generate electricity, heat homes, or fuel vehicles. The remaining digestate (solid and liquid residue) is a nutrient-rich fertilizer that can replace chemical fertilizers .

Benefits of Biogas Production from Food Waste

1. Environmental Benefits

- Reduces Greenhouse Gas Emissions: Capturing methane from food waste prevents its release into the atmosphere, where it is 25 times more potent than CO₂ as a greenhouse gas .

- Decreases Landfill Use: Diverting food waste from landfills reduces soil and water pollution caused by leachate and methane emissions .

- Promotes Circular Economy: By turning waste into energy and fertilizer, biogas production closes the loop on organic material, minimizing resource waste .

2. Economic Benefits

- Cost Savings for Waste Management: Municipalities and industries can reduce landfill disposal costs by using biogas plants .

- Revenue from Energy Sales: Excess biogas can be sold to the grid or used to power on-site operations, generating income .

- Job Creation: Biogas plants create jobs in construction, operation, and maintenance, particularly in rural areas .

3. Social and Agricultural Benefits

- Improved Soil Health: The digestate from biogas production is a natural fertilizer that enhances soil fertility and reduces the need for synthetic fertilizers .

- Energy Access in Rural Areas: Small-scale biogas systems can provide affordable energy to off-grid communities, improving living standards .

Challenges and Limitations

1. High Initial Investment

Building a biogas plant requires significant capital for digesters, gas storage, and purification systems. For example, a small-scale plant may cost $50,000–$100,000, while large industrial facilities can exceed $10 million .

2. Feedstock Variability and Availability

The amount and type of food waste available can fluctuate seasonally, affecting biogas production. For instance, restaurants may generate more waste during holidays, while agricultural residues are seasonal .

3. Technical and Maintenance Challenges

Biogas systems require regular maintenance to prevent clogs, gas leaks, and microbial imbalances. Operators need training to manage the process efficiently .

4. Energy Density and Infrastructure

Biogas has a lower energy density than natural gas, requiring larger storage volumes. Additionally, transporting biogas to distant markets may require costly infrastructure upgrades .

Applications of Biogas from Food Waste

1. Electricity and Heat Generation

Biogas can be used to power generators, producing electricity for homes, businesses, or industrial processes. The heat generated during electricity production can also be captured and used for space heating or drying crops .

2. Vehicle Fuel

Biogas can be upgraded to biomethane and used as a renewable alternative to diesel or natural gas in vehicles. This reduces emissions from transportation and lowers dependence on fossil fuels .

3. Cooking Fuel

In developing countries, biogas can replace traditional biomass fuels (e.g., firewood or charcoal), reducing indoor air pollution and deforestation .

4. Industrial Uses

Biogas can be injected into natural gas pipelines or used as a feedstock for producing bio-based chemicals, such as hydrogen or methanol .

Case Studies: Successful Biogas Projects

1. California’s Food Waste-to-Energy Initiative

California has implemented a statewide program to divert food waste from landfills to anaerobic digesters. One facility, located in Sacramento, processes 100 tons of food waste daily, producing enough biogas to power 2,000 homes annually while reducing CO₂ emissions by 10,000 tons per year .

2. Sweden’s Biogas-Powered Public Transit

Sweden has converted food waste into biomethane to fuel its public buses and trucks. The city of Gothenburg, for example, operates a fleet of 150 biomethane-powered buses, reducing emissions by 90% compared to diesel vehicles .

3. India’s Rural Biogas Program

India’s National Biogas and Manure Management Programme promotes small-scale biogas plants in rural areas. These plants use food waste and animal manure to provide clean cooking fuel and fertilizer, benefiting over 4 million households .

Future Outlook

The future of biogas production from food waste looks promising, driven by technological advancements and policy support. Key trends include:

- Increased Automation: Smart sensors and AI will optimize digester performance, reducing labor costs and improving efficiency .

- Integration with Renewable Energy Systems: Biogas will be combined with solar and wind power to create hybrid energy systems, ensuring a stable energy supply .

- Policy Incentives: Governments worldwide are introducing subsidies and tax credits to encourage biogas adoption, such as the Renewable Energy Directive in the European Union .

Conclusion

Biogas production from food waste is a powerful solution to the twin challenges of waste management and renewable energy. By converting organic waste into a clean-burning fuel, we can reduce greenhouse gas emissions, improve soil health, and create economic opportunities. While challenges remain, continued innovation and investment will unlock the full potential of biogas, paving the way for a more sustainable future.

References

Renewable Biogas Energy: Fundamentals and Applications.

Turning Food Waste into Bioenergy: A Profitable Solution for a Circular Economy.