Pyrolysis vs. Gasification: Which Tech Fits Your Waste Stream?

Introduction

As the world seeks sustainable waste-to-energy solutions, pyrolysis and gasification have emerged as two leading thermal conversion technologies. Both processes transform organic waste into valuable energy products—but they operate differently and suit distinct types of waste streams.

This article compares pyrolysis and gasification in depth, examining their:

✔ Process mechanisms

✔ Feedstock requirements

✔ Output products

✔ Environmental impacts

✔ Best-use cases

By the end, you’ll know which technology aligns with your waste management or energy recovery goals.

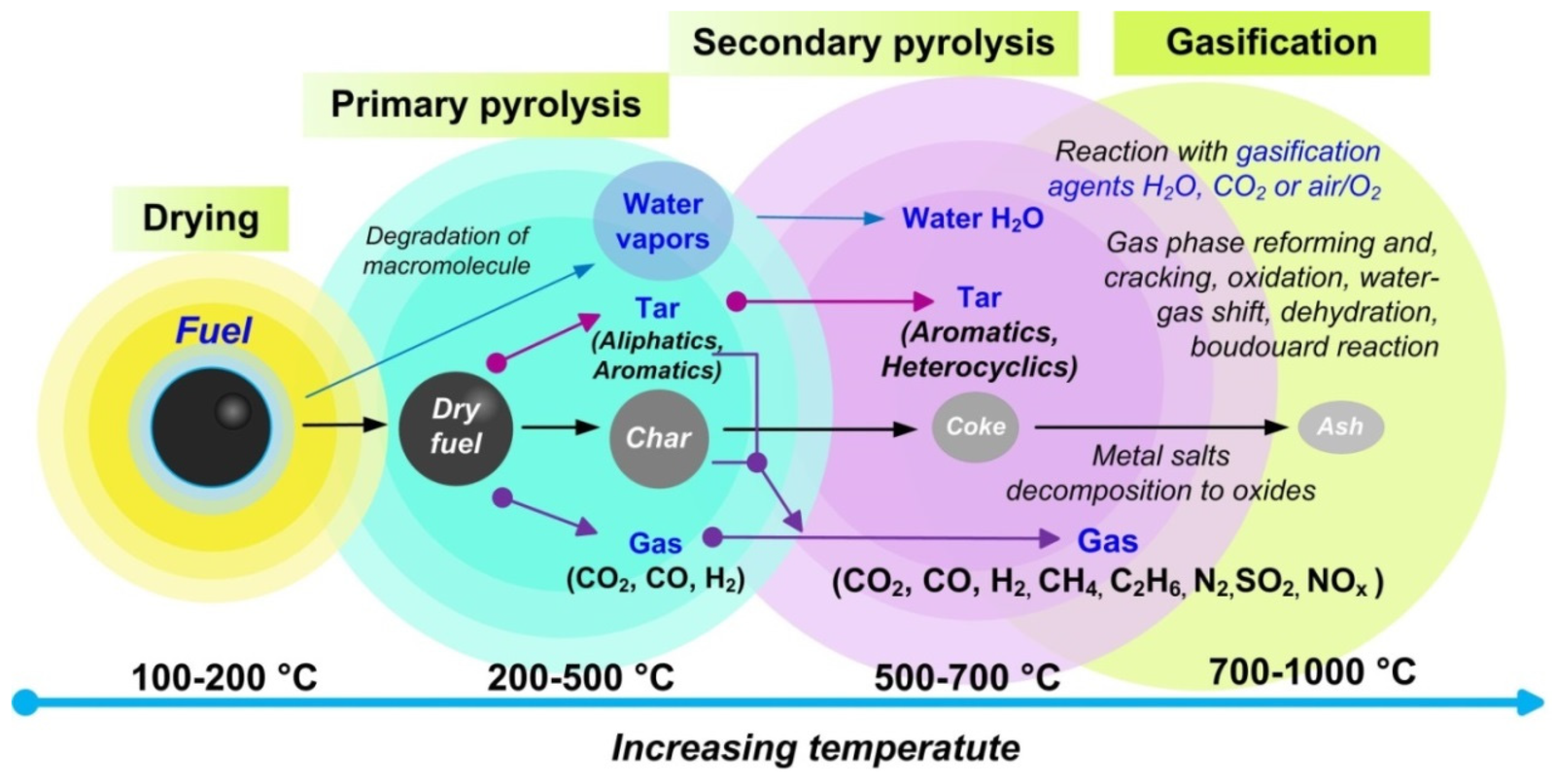

1. How Pyrolysis Works

Process Overview

Pyrolysis thermally decomposes organic materials in the absence of oxygen at temperatures between 300°C–800°C (572°F–1,472°F). The products include:

- Bio-oil (liquid fuel)

- Syngas (a mix of H₂, CO, CH₄)

- Biochar (solid carbon-rich residue)

Types of Pyrolysis

| Type | Temperature | Residence Time | Primary Output |

|---|---|---|---|

| Slow | 300–500°C | Hours–days | Biochar |

| Fast | 500–800°C | Seconds–minutes | Bio-oil |

| Flash | >800°C | <1 second | Syngas |

Ideal Feedstocks

✅ Plastics (especially waste polyethylene)

✅ Biomass (wood, crop residues)

✅ Rubber tires

✅ Municipal solid waste (MSW)

Advantages

- Produces liquid fuels (bio-oil) for transport or heating.

- Biochar improves soil fertility and sequesters carbon.

- Lower emissions than incineration.

Limitations

- Requires pre-sorted waste (contaminants reduce efficiency).

- Bio-oil needs upgrading for commercial use.

2. How Gasification Works

Process Overview

Gasification converts carbon-based materials into syngas (CO + H₂) by reacting them with limited oxygen or steam at 700°C–1,500°C (1,292°F–2,732°F). The syngas can be burned for energy or converted into:

- Electricity (via turbines)

- Hydrogen fuel

- Methanol or diesel (Fischer-Tropsch process)

Gasifier Types

| Type | Description | Best For |

|---|---|---|

| Fixed-bed | Updraft/downdraft | Biomass, MSW |

| Fluidized-bed | High efficiency | Uniform feedstocks |

| Plasma | Ultra-high temps | Hazardous waste |

Ideal Feedstocks

✅ Mixed MSW (with high organic content)

✅ Sewage sludge

✅ Coal/biomass blends

✅ Medical waste

Advantages

- Handles heterogeneous waste (less sorting needed).

- Syngas is versatile (power, fuel, chemicals).

- Higher energy recovery efficiency than pyrolysis.

Limitations

- Tar formation can clog systems.

- Requires consistent feedstock quality for optimal output.

3. Key Differences: Pyrolysis vs. Gasification

| Factor | Pyrolysis | Gasification |

|---|---|---|

| Oxygen Level | Zero O₂ | Limited O₂/steam |

| Temperature | 300–800°C | 700–1,500°C |

| Primary Output | Bio-oil, biochar | Syngas |

| Feedstock Flexibility | Needs clean, sorted waste | Tolerates mixed waste |

| Energy Efficiency | 60–70% | 70–85% |

| Capital Cost | Lower | Higher |

4. Which Technology Fits Your Waste Stream?

Choose Pyrolysis If You Have:

- Plastic or tire waste → Maximizes liquid fuel recovery.

- Agricultural residues → Produces soil-enhancing biochar.

- Pre-sorted organic waste → Ensures high-quality bio-oil.

Choose Gasification If You Have:

- Mixed MSW → Handles diverse materials (e.g., food, paper, wood).

- High-moisture waste → Steam reacts well in gasifiers.

- Need for electricity → Syngas fuels turbines effectively.

5. Environmental & Economic Considerations

Emissions Comparison

- Pyrolysis: Lower NOₓ/SOₓ (no combustion), but VOC risks from bio-oil.

- Gasification: Near-zero particulate emissions; syngas cleaning reduces toxins.

Carbon Footprint

- Both technologies reduce landfill methane emissions.

- Biochar from pyrolysis offers long-term carbon sequestration.

Cost Analysis

| Cost Factor | Pyrolysis | Gasification |

|---|---|---|

| Setup Cost | $500K–$2M | $1M–$5M |

| Operational Cost | Moderate | Higher (due to O₂/steam input) |

| ROI Timeline | 3–5 years | 5–10 years |

6. Real-World Applications

Pyrolysis in Action

♻ Plastic Waste Recycling – Companies like Agilyx convert non-recyclable plastics into crude oil.

🌱 Biochar Production – Cool Planet enriches soils using pyrolysis-derived biochar.

Gasification Success Stories

⚡ Waste-to-Energy Plants – Enerkem gasifies MSW to produce ethanol in Canada.

🏭 Industrial Scale Hydrogen – Air Products uses gasification for clean H₂ from waste.

7. The Future of Thermal Waste Conversion

- Hybrid Systems: Combining pyrolysis + gasification for higher efficiency.

- AI Optimization: Machine learning improves feedstock sorting and reactor control.

- Policy Support: Governments incentivize these technologies to meet Net Zero goals.

Conclusion: Which Tech Wins?

The best technology depends on your waste stream and end goals:

- Pyrolysis excels for liquid fuel and biochar production from clean, sorted waste.

- Gasification dominates for electricity generation from mixed or high-moisture waste.

For municipalities and industries, gasification offers broader waste compatibility, while pyrolysis suits targeted resource recovery. As both technologies advance, they’ll play pivotal roles in the circular economy—turning waste into wealth while cutting emissions.

Need help selecting a system? Consult a waste-to-energy expert to match your feedstock to the right solution!